Please find below contact details

and contact us today! Our experts always ready to help you.

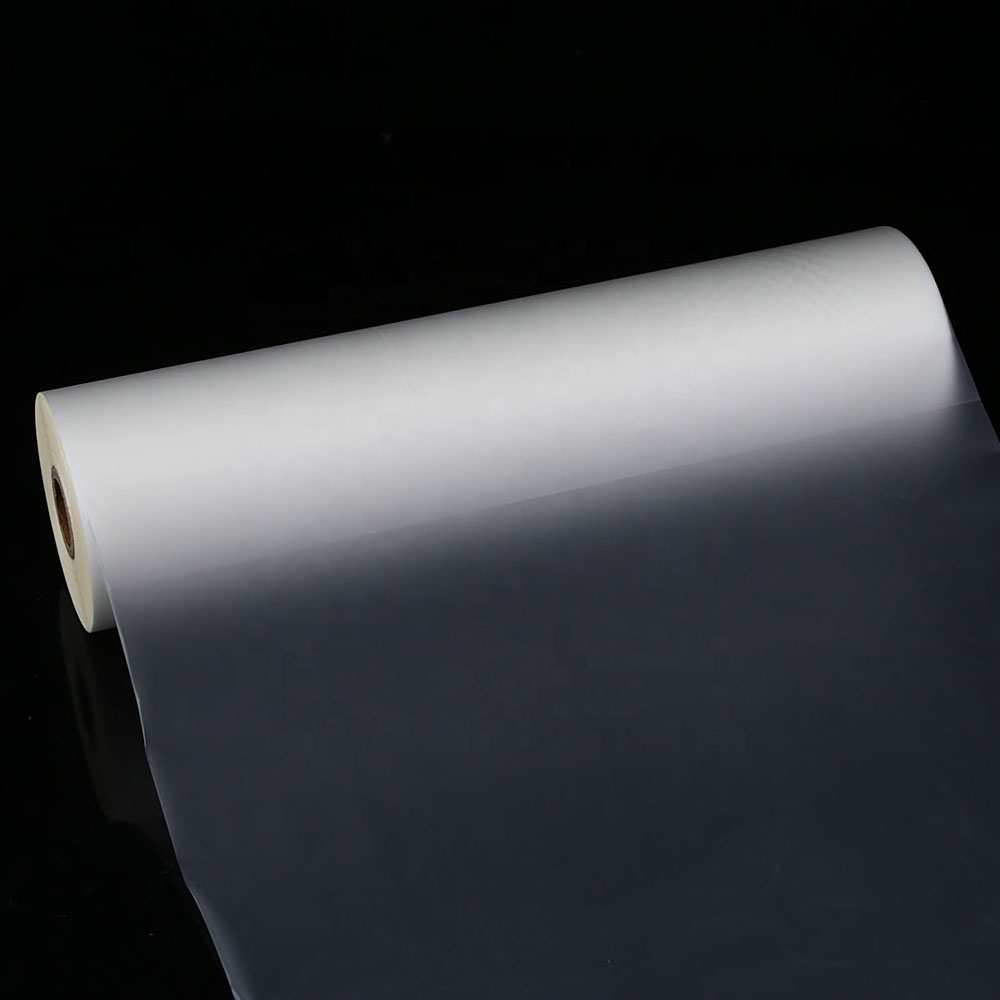

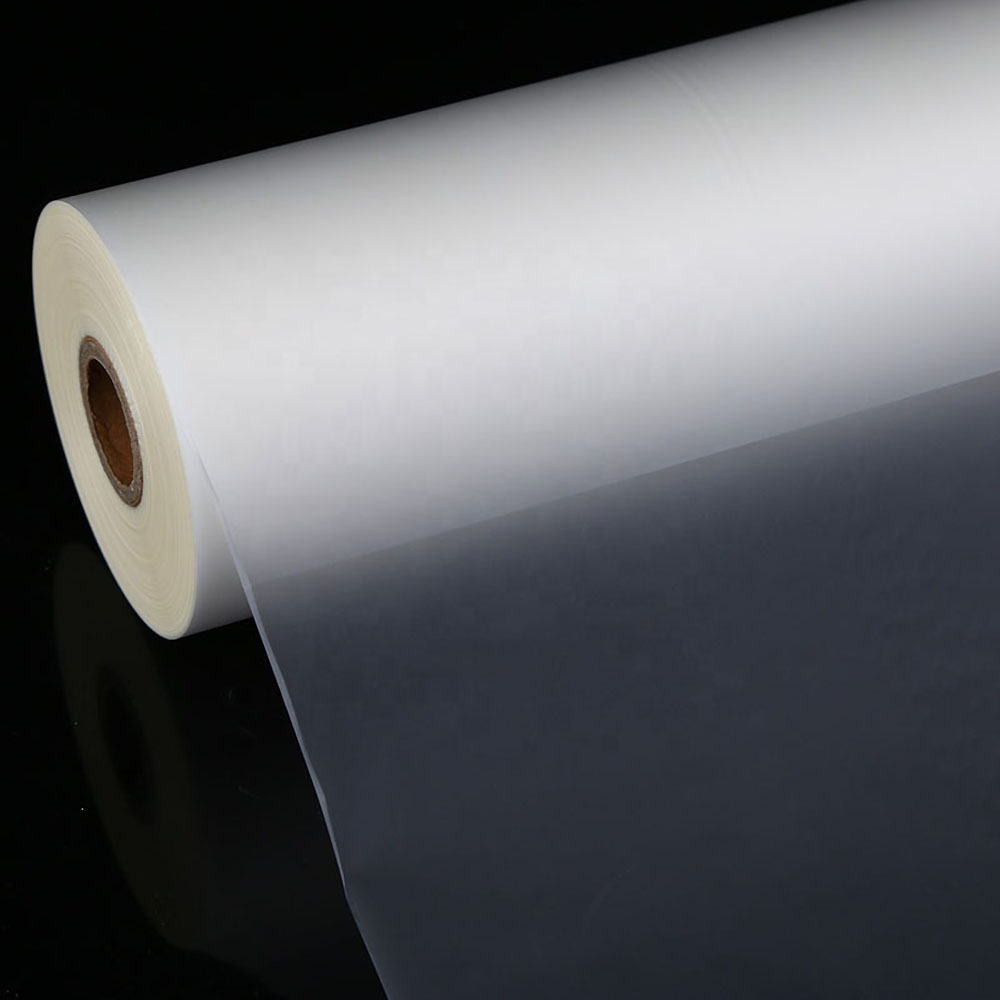

BOPP Thermal Laminating Film is mainly made of BOPP + EVA.

we use extrusion coiating process to combine this two layers.

This product has two classifications: glossy/shine/transparent and matte/opaque, both of which sees thickness from 20micron to 30micron. its width could be from 200mm to 1520mm and length from 100m (1 inch core, 25mm) to 3000m (3 inch core, 76mm)

ADVANTAGE:

1) It is easy to operate on the laminator. High productivity, energy-saving and labor-saving.

2) It was no bubble, wrinkle or desquamates.

3) Non-toxic, Odorless, Pollution Free.

4) Low Static, Wear Resistance and Long Ageing of Corona.

5) Few Defects and Good Opening.

6) Clean and High Transparency.

7) Strong powder absorption

USAGE:

1) Cover on the paper, such as books, magazines, calendars and maps and paper bags, etc.

2) Any types of boxes, just like gift box and carton box.

Medicine, advertisements, cosmetics, digital printing and showing board.

OPERATION PARAMETERS:

1) Film laminating equipment: dry or wet type film laminator

2) Temperature of hot roller: general printing material -- 85~100°C

3) Special printing material: 100~110°C

4) Pressure: 10~18Mpa

5) Speed: 8~50m/min

Once the temperature of the hot roller meets the requirements, film laminating can be done at any time, with no need of professional skill. It is provided with strong powder absorption and can blister and film release after being concaved or protruded. Matte lamination film is also suitable for partially UV glazing after film laminating, thermo printing, screen printing and frosted processes.

Package: